Non-Destructive Testing (NDT) in Structural Audits: A Comprehensive Guide

Non-destructive testing (NDT) is a pivotal tool in structural audits, ensuring safety and reliability without causing damage to the structure. In this blog, we will explore the various types of NDT methods, their applications, and their significance in identifying structural flaws, assessing material properties, and planning maintenance strategies.

What is Non-Destructive Testing (NDT)?

NDT refers to a collection of techniques used to evaluate the properties of a material, component, or structure without causing any physical damage. It is an essential part of structural audits as it helps engineers detect defects, assess material integrity, and predict the lifespan of a structure.

Importance of NDT in Structural Audits

- Preservation of Structure Integrity: NDT ensures that no harm is caused to the structure during testing.

- Accurate Diagnosis: Helps identify hidden flaws such as cracks, voids, and corrosion.

- Cost-Efficiency: Prevents the need for destructive sampling, reducing repair costs.

- Safety Enhancement: Detects potential risks before they lead to catastrophic failures.

Key Non-Destructive Testing Methods

1. Ultrasonic Testing (UT)

- How it Works: High-frequency sound waves are transmitted into the structure, and reflections are analyzed.

- Applications: Detects internal cracks, voids, and material thickness.

- Advantages: High accuracy and penetration depth.

2. Rebound Hammer Test (Schmidt Hammer)

- How it Works: Measures the surface hardness by analyzing the rebound of a spring-loaded hammer.

- Applications: Estimates compressive strength of concrete.

- Advantages: Simple and portable.

3. Ground Penetrating Radar (GPR)

- How it Works: Uses electromagnetic waves to detect subsurface anomalies.

- Applications: Locates rebar, voids, and moisture intrusion.

- Advantages: Provides detailed subsurface imaging.

4. Radiographic Testing (RT)

- How it Works: Uses X-rays or gamma rays to create an image of internal features.

- Applications: Detects cracks, porosity, and inclusions.

- Advantages: High resolution and permanent records.

5. Infrared Thermography

- How it Works: Captures thermal images to detect temperature variations.

- Applications: Identifies moisture intrusion, delamination’s, and insulation defects.

- Advantages: Non-intrusive and provides real-time analysis.

Steps in Conducting NDT in Structural Audits

- Assessment of Requirements: Understanding the structure’s history and audit objectives.

- Selection of Methods: Choosing the appropriate NDT techniques based on the material and defect type.

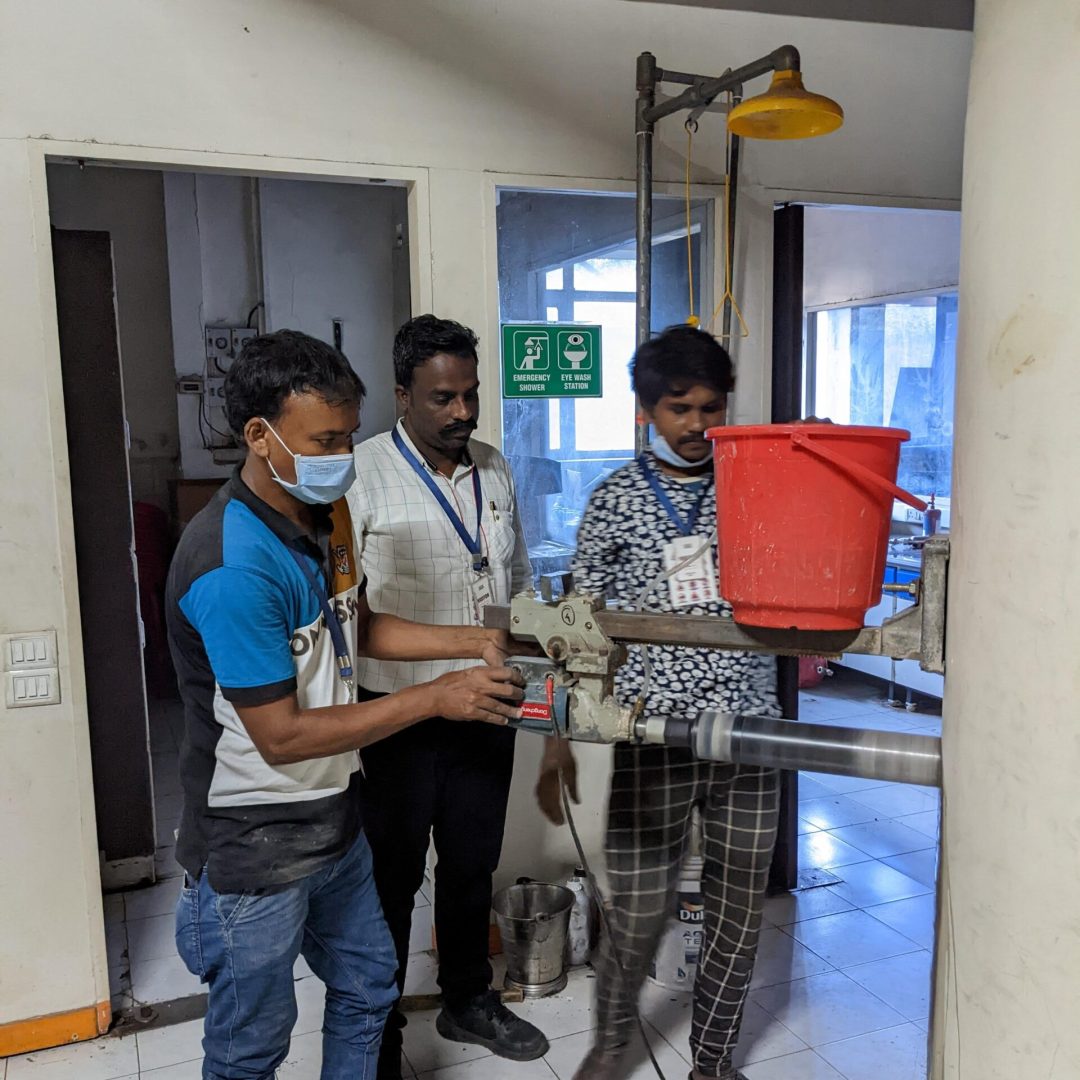

- Data Collection: Performing tests using advanced equipment.

- Analysis and Interpretation: Evaluating results to identify anomalies.

- Reporting and Recommendations: Providing actionable insights for repair or maintenance.

Benefits of NDT for Structural Integrity

- Prolongs Lifespan: Early detection of flaws helps in timely repairs.

- Cost Savings: Reduces unnecessary demolitions and reconstructions.

- Enhanced Safety: Minimizes risks of sudden failures in critical structures.

Applications of NDT in Structural Audits

- Bridges and flyovers.

- High-rise buildings.

- Industrial facilities.

- Heritage structures.

- Dams and reservoirs.

Conclusion

Non-destructive testing plays a crucial role in structural audits by offering accurate and reliable insights into the health of a structure. By employing advanced NDT techniques, structural engineers can ensure safety, efficiency, and cost-effectiveness, making it an indispensable tool in modern construction and maintenance.

Great insights on how Non-Destructive Testing (NDT) plays a crucial role in structural audits. Just like in chess, where every move is analyzed without disturbing the board, NDT helps engineers assess the true strength and safety of structures without causing damage. A very informative and well-explained guide—useful for professionals and property owners alike. Kudos to the team for breaking down a complex topic so clearly!

— SMCA Chess Academy